What is a Hot Runner?

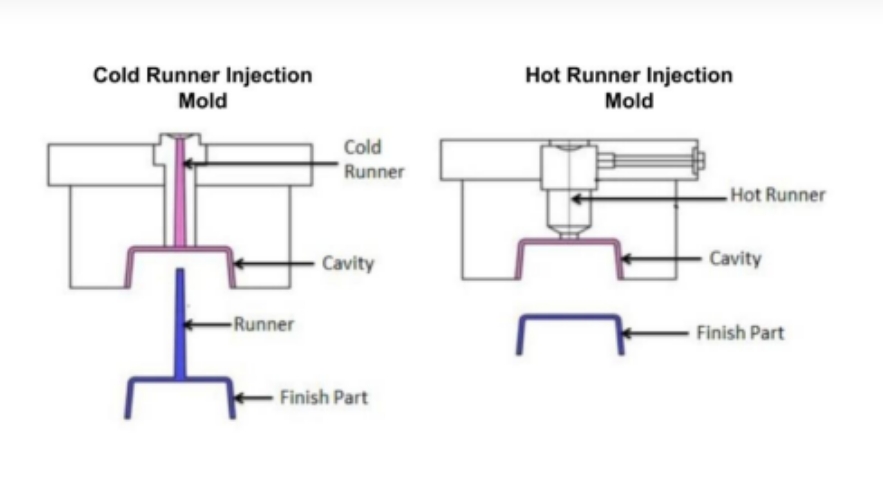

A hot runner system (used in the injection molding industry) is an internally heated system added to a plastic injection mold for molding single parts or multiple parts simultaneously. Hot runners eliminate the cold sprue or cold runner and inject the molten plastic directly into the part cavity of a plastic injection mold.

When molding two or more parts, a hot runner uses a heated manifold and nozzles to deliver the molten plastic to each part’s cavity location. When the part is ejected from the mold cavities, a small gate vestige may be visible on the part where the molten plastic enters the cavity from the hot runner nozzle. The hot runner system is controlled by a temperature controller, which is set to the melt temperature of the material and maintains this temperature throughout the molding process.

A hot runner system reduces mold cycle time, scrap, and secondary operations by removing a cold runner and sprue. These factors make hot runner systems a favorably sustainable technology by reducing plastic waste and energy consumption.